I’m excited to share that I’ve just added an Epson XP-25000 to my screen printing…

Mastering Micro-Registration

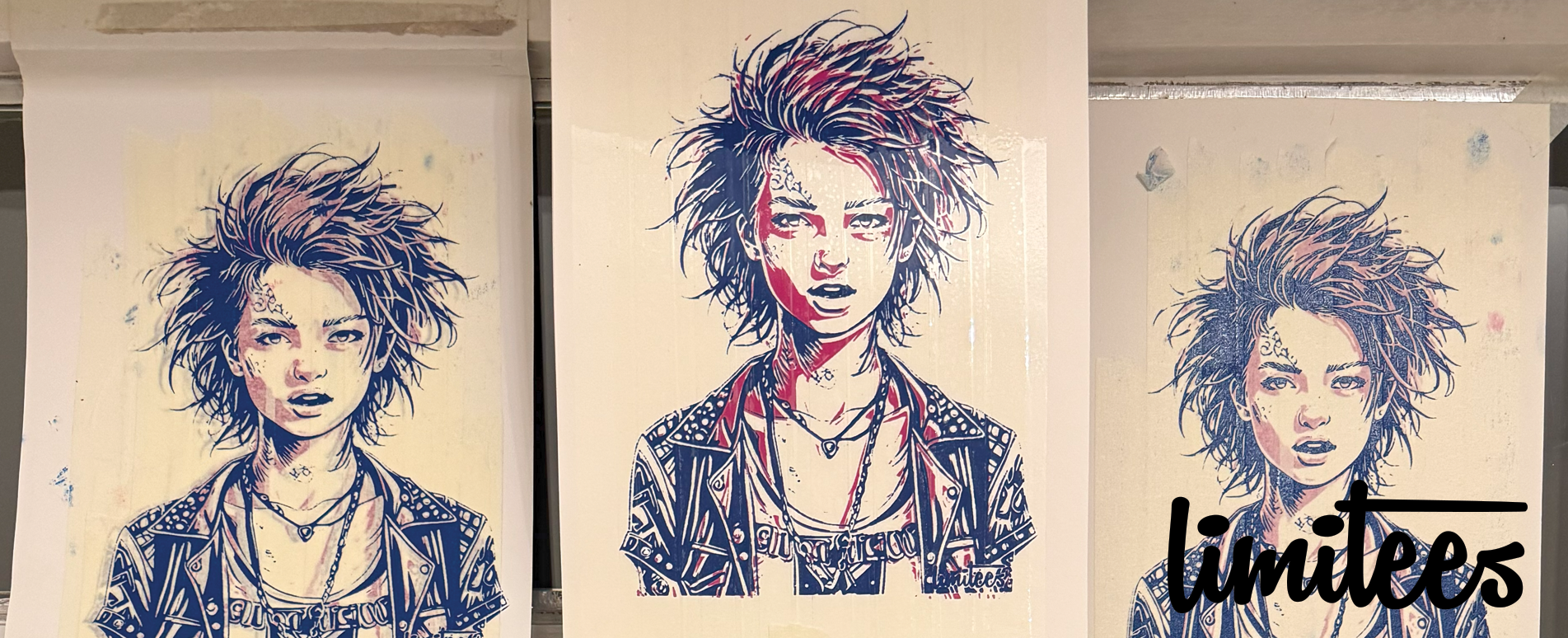

At first, I thought it would be as easy as setting up the screens, making small adjustments, and printing away. But I quickly learned that even the tiniest misalignment could throw off the entire design. A fraction of a millimetre in the wrong direction and suddenly, outlines didn’t match, colours overlapped poorly, and the print looked off.

To really get a feel for the process, I started testing alignment by printing onto cotton paper with a single colour. Once that layer was down, I used tape to cover it and then printed the next layer on top. This allowed me to see exactly how the colours aligned without wasting materials. It was a simple but effective way to check my registration before committing to a full run on fabric.

The only way to get better was through trial and error. I spent hours tweaking screens, testing different methods, and learning how pressure, off-contact distance, and screen tension all played a role. I had to develop a feel for how much to adjust the micro-registration knobs and how to check alignment before going all in.

Over time, I started to trust the process. Now, instead of frustration, I see micro-registration as a skill that comes with patience and practice. It’s one of those things you can’t truly understand until you do it yourself—again and again.

If you’re new to screen printing, my advice is simple: expect mistakes, embrace the learning process, and keep printing!